70 years ago, JE Pistons was founded in Huntington Beach, California, with the goal of providing performance aftermarket and racing enthusiasts with the strongest and highest quality forged pistons in the industry, while everyone else was still producing cast designs. Today, JE is a leader in the development and production of off-the-shelf and custom forged pistons and auxiliary components that engine builders, professional race teams, and amateur racers from all over the world rely on.

JE’s products can be found compressing the fuel and air pulled into some of the highest horsepower engines from top-tier organizations such as IMSA, NASCAR, NHRA, ARCA, NMCA, and even AMA Supercross for pro powersport builds. In the video above, the leaders from a few of JE’s manufacturing departments give us a tour of their manufacturing facility in Ohio, displaying some of the latest and greatest piston manufacturing equipment in the world.

One area where JE really stands out is in their commitment to keeping jobs in America. None of the manufacturing process is outsourced, and every step from initial forging to final machining is done in-house at the company’s Mentor, Ohio facility. All of the materials used are even sourced from a mill in New Jersey. Which is rare to see in the aftermarket industry, where today it’s not uncommon for manufacturers to source their materials from China and outsource manufacturing duties across Asia.

Because “engineering is at the foundation” of everything they do, JE employs only the best trained engineers, machinists, technicians, and sales specialists who are mostly road racers, drag racers, and general car enthusiasts themselves — they eat, sleep and breathe this stuff.

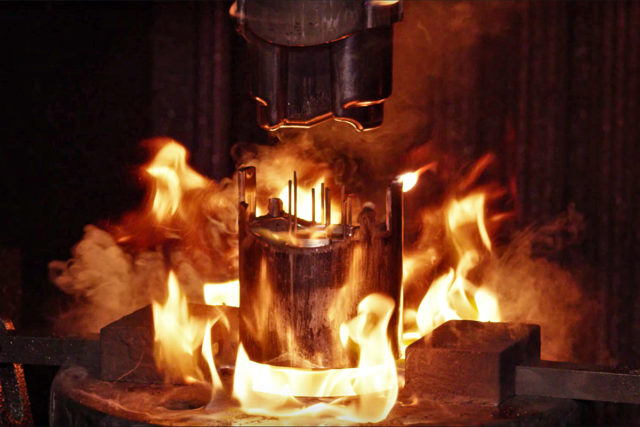

Beyond that, the company then provides their staff with the newest tools, CNC machines, programming software, CAD software, and purpose-designed forgings. Doing this all in-house allows JE to oversee every aspect of the manufacturing process, which enables the company to hold their products to some of the highest quality control standards out there. Even keeping tolerances to within millionths of an inch!

JE Pistons employs only the best trained engineers, machinists and technicians in their manufacturing facility; then provides them with state-of-the-art tools, equipment and software.

When JE’s engineers begin developing an off-the-shelf piston for a new application, they start by creating at least 10 different iterations of the piston. From there each design will be tested, improved, tested again — continuing this loop as many times as needed — then the design is validated to guarantee they are supplying their customers with the best performing product, all before the public even knows it exists.

While the company does offer countless off-the-shelf piston options for many of the most popular motorsports and powersports applications, what their team really looks forward to is the challenge of designing a custom slug for an off-the-wall or unknown application. It’s JE Piston’s belief that their openness to the crazy ideas that their customers approach them with are what influences their out-of-the-box thinking and sparks innovation, keeping them ahead of the pack and further progressing the industry as a whole.