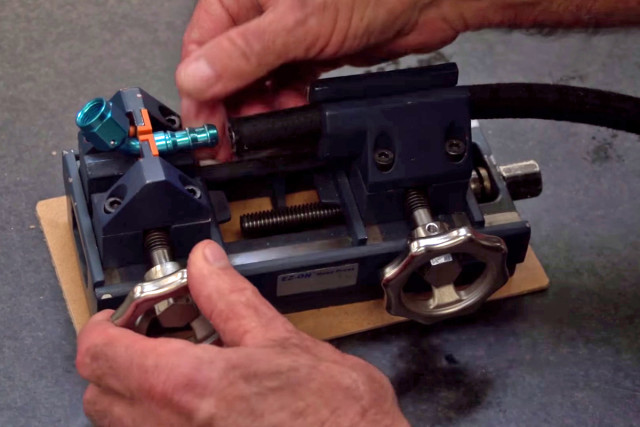

One of the most challenging aspects to building and assembling a quality race engine is transferring fluids – oil, water, and fuel – from one place to another. As leak-free performance is the ultimate goal, AN fittings have become the standard in performance applications, but they can be incredibly frustrating to assemble especially for the first-timer. Sliced fingertips, lots of cursing, tool-throwing – you get the idea. Koul Tools has the answer to all of your frustrations in the form of their EZ-On Hose Press, which we’ve featured here before.

It’s designed to work with nylon-wrapped push-on style hose and hose ends, which offer a number of benefits to the user over the aforementioned stainless-steel hose and ends – most importantly weight savings, which is always important in a racing application.

Using the Hose Press is one of the simpler tasks we’ve seen, and in this video, inventor Dick Raczuk covers a number of tips to make the installation of press-fit hose and ends using the tool simpler and more effective for users.

Specifically, he notes that users have reported that installing 90-degree fittings with a tight radius has proven challenging – but he has the solution. By installing the next-larger-sized set of hose end inserts than what is typically required, the tight 90-degree fitting can now be held in the press and provide enough wiggle room to press the hose on without much drama.

Raczuk has invented not only the EZ-On Hose Press, but also the company’s namesake Koul Tools, which allow for simple installation of those frustrating stainless-steel braided hose and hose ends using nothing more than a simple shop vise.

The EZ-On Hose Press is one of the more interesting tools we’ve seen in some time, and in action it’s a serious time-saver.

For more information on Koul Tools, check out their website.